In the past I've drilled the hose clamp fastener heads out and wired them. Running short on bits now and looked over the rulebook and the clamps aren't "nuts or fittings that drain fluid when removed"... do the coolant hose clamps need to be drilled and wired? Did a search but couldn't find a post to clarify.

Things drilled so far (for sanity check - pls point out if I'm missing anything):

Brake caliper mounting bolts

Axles and Axle Nuts

Oil Drain Plug and filler

Coolant drain plug and filter

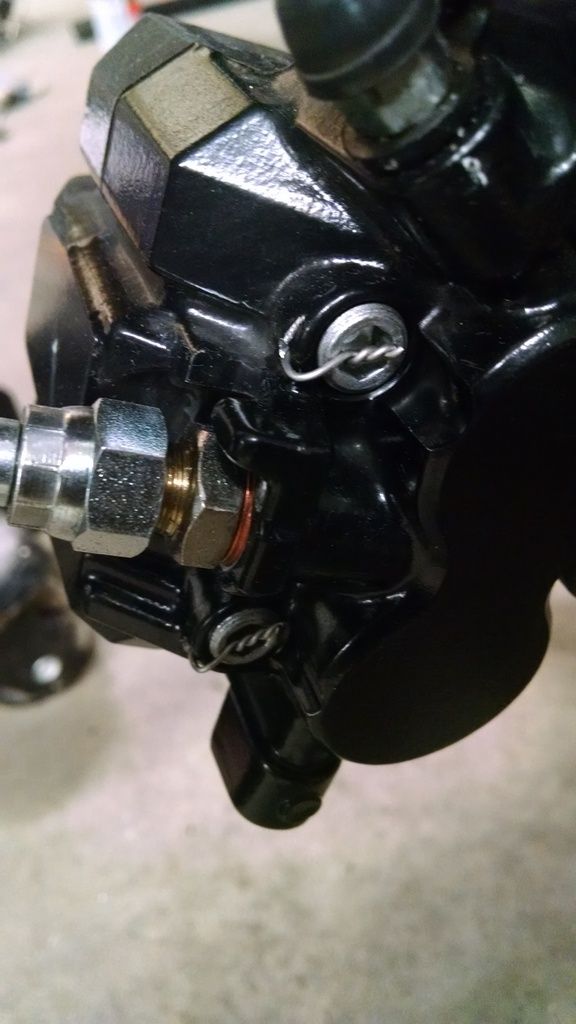

Brake banjo bolts (coming up)

Thanks!

Jim

Reply With Quote

Reply With Quote